Bitumen Based Coating Enamel Grade C

Bitumen Based Coating Enamel is a bituminous compound reinforced with inert non-fibrous fillers for hot application. Type 2 a, b and c comply with BS 4147: 1980. It will soften gradually when heated and will change back to solid on cooling.

USAGE

Bitumen Based Coating Enamel is mainly used as anti-corrosion materials for protection of iron and steel pipes for industrial and drinking water.

TECHNICAL ADVANTAGES

Excellent and permanent adhesion to metal

Low water absorption

Impact resistance

Flexibility

Resistance to soil stress

Resistance to cold stress

High electrical resistibility

Chemically stable

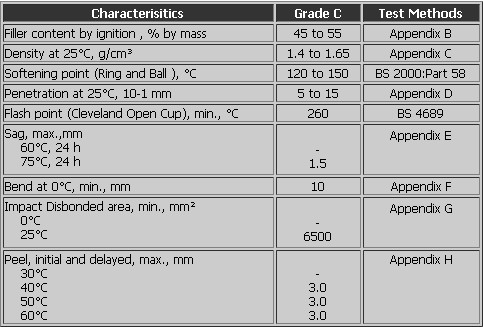

SPECIFICATIONS

APPLICATION AND HANDLING

Surface Preparation

The surface of the steel pipe to be coated with Bitumen Based Coating Enamel shall

be wire-brushed to remove all surface rust, mill scale and loose materials. Immediately

after wire brushing the surface shall be wiped clean and dried, then apply a coat of

Bituminous Primer and allowed to dry.

Application

Bitumen Based Coating Enamel shall be broken up into small pieces and heated

slowly to the application temperature of 220°C to 250°C, and should not be heated

to a temperature exceeding 270°C.

DRUMMING OPTIONS

(Grade A+) Brand New Drum

(Grade A) Recondition Drums .

External painted in Black

Internal washed and 100% cleaned

(Grade B) Recondition Drums .

External painted in Black

Internal containing 2 to 3 Kg

Foreign material .

(Grade C) Recondition Drums .

External unpainted .

Internal containing 2 to 3 Kg Foreign material .

Paper Packing

2 Ply paper bag +1 Ply Poly Bag = 3 Ply Paper Bag in Net Weight 50/25 kgs bags